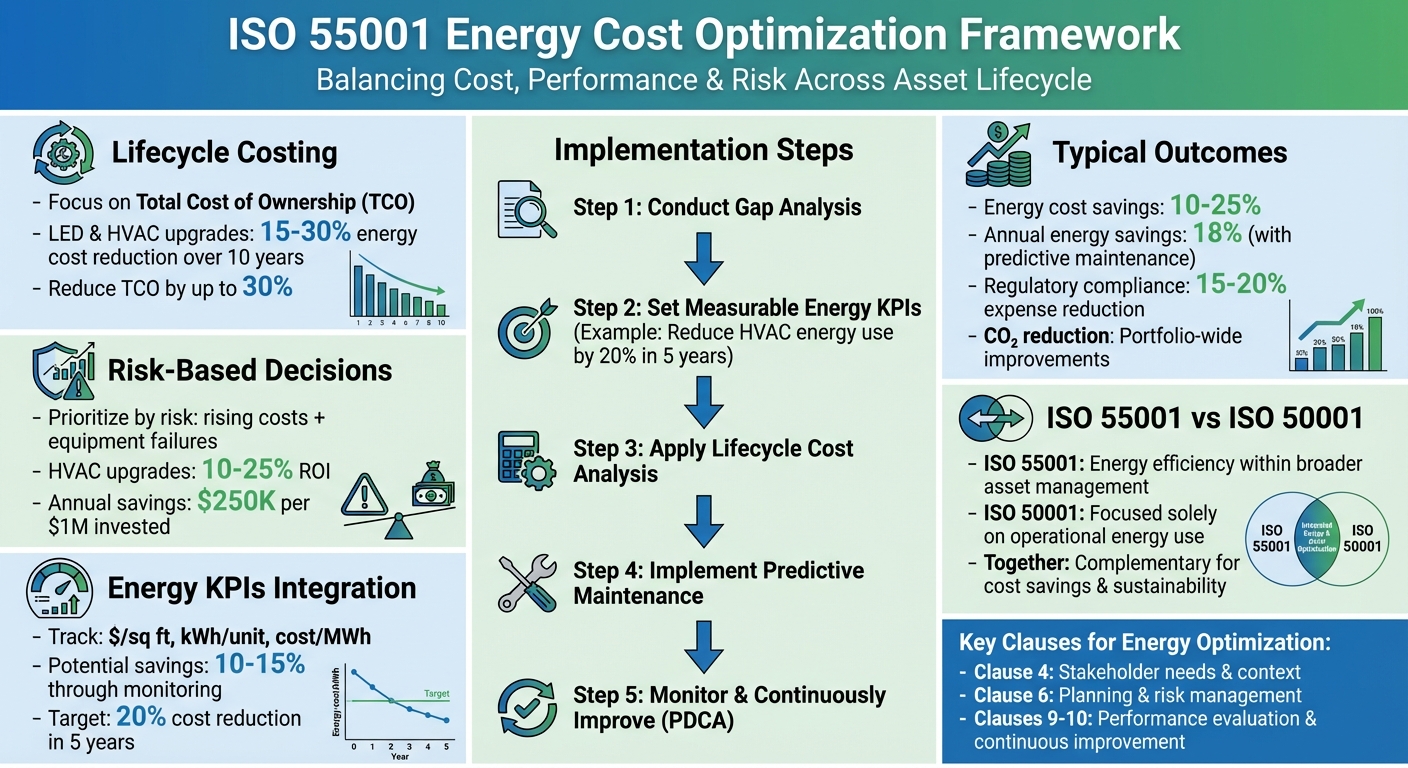

ISO 55001 helps organizations manage assets effectively by balancing cost, performance, and risk over an asset’s lifecycle. When applied to energy management, it enables businesses to reduce energy costs, improve asset efficiency, and align energy goals with overall business objectives. Key takeaways include:

- Lifecycle Costing: Focus on total cost of ownership (TCO), not just upfront costs. For example, energy-efficient upgrades like LED lighting or HVAC optimization can cut energy expenses by 15–30% over a decade.

- Risk-Based Decisions: Prioritize energy investments by assessing risks like rising energy costs or equipment failures. For instance, upgrading inefficient systems may save thousands annually.

- Energy KPIs: Use metrics like energy cost per square foot to measure performance and integrate them into asset management plans.

ISO 55001 differs from ISO 50001 by addressing energy efficiency as part of broader asset management, while ISO 50001 focuses solely on operational energy use. Both standards complement each other to drive cost savings and sustainability goals.

To implement ISO 55001 for energy optimization:

- Conduct a gap analysis of current practices.

- Set measurable energy KPIs (e.g., reduce HVAC energy use by 20% in 5 years).

- Use lifecycle cost analysis and predictive maintenance to prioritize energy-efficient investments.

ISO 55001 Energy Optimization: Key Benefits and Implementation Framework

How ISO 55001 Supports Energy Efficiency and Cost Savings

Lifecycle Costing and Energy Efficiency

ISO 55001 encourages organizations to consider the entire lifecycle of an asset rather than just its initial cost. Instead of focusing solely on the purchase price, the standard emphasizes life-cycle costing, which includes expenses related to acquisition, energy use during operation, maintenance, and eventual disposal. This approach reveals the true total cost of ownership (TCO) and highlights the long-term value of investing in energy-efficient solutions.

Take this example: a study of a U.S. municipal building found that implementing LED retrofits, optimizing HVAC systems, and replacing boilers with high-efficiency models could cut energy costs by 15–30% over a decade. While these upgrades might require higher upfront capital expenditure (CAPEX), the long-term operational savings (OPEX), measured in dollars per kilowatt-hour ($/kWh), make them worthwhile. By following ISO 55001’s framework, organizations can reduce TCO by as much as 30%, thanks to investments that curb energy waste throughout the asset’s lifecycle.

This holistic view of costs helps organizations prioritize energy-efficient investments more effectively.

Risk-Based Prioritization of Energy Investments

ISO 55001 also requires organizations to assess and rank risks – such as escalating energy costs or potential equipment failures – and prioritize projects accordingly. This ensures that energy-related upgrades are evaluated not just for their immediate benefits but also for their ability to reduce financial risks and deliver long-term savings.

For example, a risk matrix might rank an HVAC system upgrade as a higher priority than minor aesthetic repairs if the HVAC system is a significant source of energy inefficiency or prone to frequent breakdowns. This kind of prioritization leads to measurable returns, including lower energy bills, reduced downtime, and fewer equipment failures. Tools like Oxand Simeo™ can model these scenarios, allowing organizations to compare projects based on metrics like CO₂ saved per kilowatt-hour per dollar invested. Such tools also help create multi-year CAPEX and OPEX plans that balance cost, risk, and carbon reduction goals.

By embedding risk considerations into asset planning, organizations can align their energy investments with broader performance and sustainability objectives.

Aligning Energy KPIs with Asset Management Goals

ISO 55001 connects energy performance indicators (KPIs) with broader asset management metrics, such as reliability and availability. Common energy KPIs include energy cost per megawatt-hour, energy cost per square foot, and kilowatt-hours consumed per asset unit. These metrics directly support organizational goals like cost reduction and sustainability.

This alignment happens through the Strategic Asset Management Plan (SAMP), where energy KPIs are tracked alongside asset performance. For instance, monitoring energy cost per square foot can highlight opportunities for timely maintenance, potentially delivering 10–15% savings. By embedding these KPIs into dashboards and management reviews, organizations can set clear targets – such as reducing energy costs per square foot by 20% over five years – and ensure that energy performance remains a key factor in all asset-related decisions.

Integrating energy KPIs into asset management strategies ensures that energy efficiency is not just a side goal but a core part of achieving broader organizational objectives.

ISO 55001 Explained: The Ultimate Guide to Asset Management Systems

Key ISO 55001 Clauses for Energy Cost Optimization

Building on the principles of strategic asset management, certain clauses within ISO 55001 play a pivotal role in optimizing energy costs.

Context of the Organization and Stakeholder Needs

Clause 4 of ISO 55001 emphasizes understanding external and internal factors that influence an organization’s asset management system. This includes energy regulations, carbon reduction goals, and utility rate structures. It also requires identifying stakeholder needs, such as regulatory agencies enforcing emissions standards (e.g., the EPA), utilities impacting costs through pricing models, investors pushing for decarbonization, and customers expecting environmentally responsible practices.

In practical terms, organizations should create a stakeholder register to document these requirements, ensuring they are integrated into the asset management scope. For example, a U.S.-based utility might prioritize upgrading HVAC systems to meet carbon reduction goals while managing rising energy costs. Tackling regulatory and financial risks like these can reduce energy expenses by 15–20%. In states with strict decarbonization mandates – such as California’s SB 100, requiring 100% clean energy by 2045 – Clause 4 provides a structured approach for aligning these goals with the Strategic Asset Management Plan (SAMP). Conducting a thorough stakeholder analysis can help prioritize impactful investments, such as solar energy systems, which could reduce utility dependency by 30%.

By clearly defining stakeholder needs, organizations can better target energy risks and align their planning efforts accordingly.

Planning and Risk Management

Clause 6 focuses on setting asset management objectives and planning actions to address risks and seize opportunities. For energy cost optimization, this involves identifying risks like fluctuating energy prices, aging infrastructure, and peak demand charges, then evaluating their likelihood and potential impact. For instance, a pump failure could lead to $10,000 in monthly energy waste, making it a high-priority issue to address.

Effective planning involves assessing risks, estimating costs, and outlining mitigation strategies. This might include evaluating whether installing variable frequency drives could cut energy use by 20%, or determining if upgrading an HVAC system could deliver a 10–25% ROI through lower operating costs. Using lifecycle cost analysis can help in decision-making. For example, investing $1 million in high-risk HVAC systems could yield $250,000 in annual savings, particularly under U.S. electricity rates of $0.07–$0.15 per kWh.

By proactively addressing these risks, organizations can make informed investments that significantly lower energy costs over time.

Performance Evaluation and Continuous Improvement

Once risks are addressed and plans are implemented, ongoing performance evaluation ensures energy cost optimization stays on track.

Clauses 9 and 10 focus on monitoring performance, conducting audits, and driving continuous improvement. Clause 9 requires tracking energy-related KPIs – such as kilowatt-hours per unit of output, energy costs per asset, or chiller efficiency – to determine if asset management objectives are being met. Clause 10 outlines how to respond when performance falls short and refine strategies over time.

For instance, a U.S. manufacturing company might monitor chiller efficiency with a target of less than 0.6 kW per ton. If audits reveal inefficiencies, predictive maintenance can be implemented to prevent further issues. This method has enabled companies to achieve 18% annual energy savings while maintaining ISO 55001 compliance. Tools like Oxand Simeo™ can further support this process by simulating energy consumption, tracking KPIs such as CO₂ reductions, and identifying areas for improvement. Applying PDCA (Plan-Do-Check-Act) cycles helps organizations refine their energy performance continuously, with reported cost savings ranging from 10–25%. By embedding energy metrics into regular management reviews and dashboards, companies can ensure energy efficiency remains a core, measurable component of their asset management strategy.

sbb-itb-5be7949

Methods to Align ISO 55001 with Energy Cost Goals

Risk-Based Lifecycle Cost Analysis

Risk-based lifecycle cost analysis takes a close look at the total cost of owning and operating an asset over its lifetime. For energy-heavy equipment like HVAC systems, lighting, boilers, and chillers, this means evaluating capital costs, energy expenses, maintenance needs, and the financial impact of unexpected failures.

Start by identifying major energy-consuming assets and creating an inventory of their energy use. Track key metrics for each asset, such as kilowatt-hour (kWh) usage, fuel consumption, utility costs, and operating hours. From there, model different scenarios – like maintenance, replacement, or upgrades – and calculate metrics like net present value (NPV) and payback periods. Use current U.S. electricity rates and factor in any available rebates to make these calculations as accurate as possible.

For instance, replacing outdated HVAC systems can lead to significant yearly energy savings while also cutting down on costs caused by sudden breakdowns. By ranking projects based on both risk reduction and potential energy savings, organizations can make a strong case for energy-efficient investments. This detailed approach helps lay out a clear plan for proactive asset management strategies.

Predictive Asset Management and Preventive Maintenance

Alongside lifecycle cost analysis, predictive management plays a key role in keeping assets running efficiently. By using data on asset conditions and performance trends, predictive asset management identifies potential problems before they escalate. This approach helps ensure assets operate close to their intended efficiency, avoiding energy waste caused by issues like clogged filters, degraded variable frequency drives, or fouled heat exchangers.

Preventive maintenance programs, aligned with ISO 55001’s lifecycle principles, should focus on energy-critical tasks. These might include cleaning coils, calibrating sensors, optimizing control settings, and maintaining insulation. Using probabilistic degradation models, teams can predict how asset efficiency might decline over time based on factors like age, environment, and workload. Even with limited monitoring, historical data, work order reports, and performance benchmarks can help estimate when maintenance is needed.

Oxand’s PredTech approach is a great example of this strategy in action. Their Oxand Simeo™ tool, backed by a database of over 10,000 aging and performance models and 30,000 maintenance guidelines, simulates how assets age, fail, and consume energy. This allows organizations to plan maintenance schedules that minimize energy waste and reduce the risk of unexpected failures – all without needing full IoT coverage.

Integrating Energy Targets into Asset Management Plans

To turn risk assessments and proactive maintenance into actionable steps, measurable energy targets should be woven into asset management plans. Start by establishing energy performance baselines at levels such as site, system, or asset class. Use at least 12 months of normalized data, adjusting for variables like weather, occupancy, or production, and express these baselines in both absolute terms (e.g., total kWh or annual costs) and intensity metrics (e.g., kWh per square foot).

Set SMART energy targets – specific, measurable, achievable, relevant, and time-bound – and link them directly to asset management decisions. For example, a target could be: "Cut HVAC electricity usage by 20% within five years through high-efficiency replacements and control upgrades." These energy KPIs should be treated as core performance metrics, alongside availability and reliability, and mapped directly to the goals outlined in your Strategic Asset Management Plan (SAMP).

When drafting multi-year CAPEX and OPEX plans, every proposed project should include a clear impact on energy baselines and targets. For example, detail how many kilowatt-hours or dollars will be saved, or how much CO₂ emissions will be avoided. This approach helps decision-makers prioritize projects that strike the best balance between cost, risk, and performance.

Conclusion

Key Takeaways

ISO 55001 provides a structured framework to effectively manage asset lifecycles, including energy-related costs, while ensuring reliable performance. By applying a lifecycle approach, you can assess energy impacts across acquisition, operation, maintenance, and eventual replacement phases.

A key element of ISO 55001 is risk-based analysis, which helps prioritize energy-efficient projects and maintenance efforts. This approach reduces kilowatt-hour usage and operating expenses without introducing unacceptable risks. The standard also emphasizes ongoing performance monitoring, enabling you to track and refine energy KPIs over time. It integrates sustainability goals, regulatory compliance, and asset investment decisions, ultimately minimizing decarbonization risks and costs.

With standardized processes for planning, operating, and maintaining assets, ISO 55001 enhances asset utilization, reduces failures, and improves reliability. The result? Less waste, lower energy consumption, and fewer unplanned downtimes – all of which extend asset life. These operational improvements align with sustainability goals by cutting fuel or electricity use, reducing emissions, and promoting more efficient resource utilization.

These insights create a foundation for taking strategic, actionable steps right away.

Next Steps for Implementation

To put these principles into action, start by evaluating your current asset and energy management practices against ISO 55001 standards. A gap analysis can reveal quick wins and areas needing improvement. Update your asset management policy to explicitly include energy performance, cost reduction (measured in dollars), and carbon reduction as key drivers of value. Identify critical energy-intensive assets – such as HVAC systems, chillers, or process equipment – and document their current energy consumption and costs.

Set measurable energy KPIs, like kilowatt-hours per square foot, that align with ISO 55001 goals. Incorporate energy criteria into investment and maintenance decisions using lifecycle cost and risk analysis. To streamline and strengthen implementation, consider collaborating with specialized partners like Oxand. Their platform, Oxand Simeo™, integrates asset, condition, and energy data into risk-based, multi-year CAPEX and OPEX plans, guiding decisions on energy investments – what to prioritize, when to act, and how much to budget. Using predictive models, Oxand helps you simulate asset aging, failure rates, and energy consumption trends, enabling you to focus on projects that deliver meaningful cost savings and reductions in both CO₂ emissions and energy use. Typical results include 10–25% cost savings on targeted maintenance and significant portfolio-wide reductions in kilowatt-hour consumption and carbon emissions.

FAQs

What is the difference between ISO 55001 and ISO 50001 when it comes to energy management?

ISO 55001 serves as a guide for managing assets throughout their lifecycle. It emphasizes improving performance, reducing risks, and integrating sustainability into asset management strategies. Energy considerations naturally become a part of this broader approach to asset management.

On the other hand, ISO 50001 is all about energy management. It provides organizations with a structured system to boost energy efficiency, cut down on energy use, and lower carbon emissions.

Although the two standards can work well together, their focus differs. ISO 55001 offers a comprehensive approach to managing all types of assets, while ISO 50001 concentrates specifically on enhancing energy performance.

How can ISO 55001 help reduce energy costs?

ISO 55001 offers a structured approach to streamline asset management while boosting energy efficiency, which can result in noticeable cost savings. By aligning asset management practices with energy objectives, organizations can cut down on waste, improve system performance, and reduce operational costs.

The process involves setting clear goals, evaluating both asset and energy data, and creating a focused plan to prioritize investments and maintenance efforts. Predictive tools like advanced modeling and data analysis play a crucial role in identifying potential issues, optimizing energy consumption, and extending the life of assets. Consistent monitoring and ongoing adjustments help maintain energy cost savings over time, all while supporting sustainability targets.

What are the benefits of using risk-based lifecycle cost analysis for energy efficiency projects?

Risk-based lifecycle cost analysis offers several benefits for energy efficiency projects. It helps organizations forecast maintenance needs with greater precision, prioritize where to allocate resources, and extend the life of their assets. By adopting this method, total ownership costs can often be reduced by as much as 30%, all while achieving energy savings and advancing environmental goals.

This approach works by aligning investment decisions with real-time data on asset performance and condition. As a result, organizations can fine-tune maintenance schedules, cut unnecessary costs, and significantly lower energy use and carbon emissions. Beyond enhancing operational efficiency, it also supports compliance with standards like ISO 55001.

Related Blog Posts

- Predictive Maintenance for Asset Management (Infrastructure and Real Estate) is critical – use the web site the web site:https://theiam.org

- Aging Infrastructure & Lifecycle Management

- Sustainability & Carbon Reduction Solutions

- Asset Investment Planning 101: How to Decide What to Invest in, When and How Much