Want to manage your assets better and meet ISO 55001 standards? Start by building a well-structured asset register. This isn’t just about compliance – it’s about smarter decision-making, reducing costs, and improving asset performance.

Here’s the key: focus on collecting the right data. The 2024 update to ISO 55001 emphasizes decision-making, predictive actions, and data management. Your asset register should include:

- Identification Data: Unique IDs, names, locations, and maintenance responsibilities.

- Condition Data: Regular ratings to track asset health and lifespan.

- Risk Data: Failure likelihood, consequences, and criticality rankings.

- Lifecycle Data: Remaining useful life, maintenance costs, and CAPEX/OPEX forecasts.

- Compliance Data: Regulatory records, energy metrics, and certifications.

A clear hierarchy connects day-to-day details with long-term plans, ensuring your register supports audits and aligns with business goals. Start small, prioritize critical assets, and use tools to integrate and validate data. This approach can cut maintenance and replacement costs by 10–30% while improving efficiency.

Ready to take control of your assets? Start with a gap analysis, standardize your data, and ensure regular updates to stay audit-ready and ahead of risks.

Implementing an ISO 55001-compliant Asset Management System – Module 1

sbb-itb-5be7949

Required Data Elements for ISO 55001 Compliance

To meet ISO 55001 standards, your asset register should include only essential data. The 2024 update emphasizes that properly configured data is the foundation for effective decision-making [1]. Each category of data in your register plays a critical role in supporting compliance and driving smart asset management strategies.

Asset Identification Data

Every asset needs a unique identifier to ensure it can be tracked across systems. Standardized classification methods, like Uniclass or RICS NRM, help maintain consistency. You’ll also need precise location information, such as the site, building (with UPRN), floor, and room, along with details about who is responsible for maintenance [6]. For example, a gas-fired boiler might fall under "5 SERVICES" with a specific SFG20 code like 20-04.

| Field Category | Essential Data Field | Description/Example |

|---|---|---|

| Identification | Asset ID | Unique number/code for tagging or barcoding |

| Identification | Asset Name | Descriptive name (e.g., "BOILER – gas fired") |

| Classification | System/Element Group | High-level grouping (e.g., "5 SERVICES") |

| Classification | Asset Class Code | Standardized code (e.g., SFG20 code 20-04) |

| Location | Building/Block (UPRN) | Unique property reference number |

| Location | Floor & Room/Zone | Specific location (e.g., "Floor 5, Gym") |

| Responsibility | Asset Maintainer | Maintenance entity (e.g., "Supplier XX") |

Using standardized formats like COBie ensures seamless data exchange between systems or contractors. Additionally, a documented change control process is critical to track modifications, including dates, requestors, and approvals [6].

Condition and Performance Data

Condition and performance data transform your asset register into a tool for predictive decision-making. The 2024 ISO 55001 standard introduces "Predictive Action" (Section 10.3), encouraging organizations to adapt based on risks and opportunities [1].

Regularly collected condition ratings, ideally on a 1-to-10 scale, offer insights into an asset’s effective age and remaining life [7]. As PIARC emphasizes:

"Condition or performance data needs to be collected with sufficient frequency and consistency to provide a representative view of the condition of the asset and to track how this changes over time" [7].

Modern tools like IoT sensors, digital twins, and predictive analytics can enhance data collection by combining historical and real-time insights [4]. Before planning lifecycles, assess the quality and reliability of your condition data. Better data leads to stronger, more reliable strategies [8].

Risk and Criticality Data

Risk and criticality data help prioritize asset management activities based on their potential impact. ISO 55001:2024 requires organizations to address risks (Section 6.1.2) and opportunities (Section 6.1.3) to achieve desired outcomes [1].

Your asset register should include risk assessments that evaluate failure likelihood and consequences. Documenting failure modes and conducting impact analyses – considering operational, financial, safety, and environmental factors – are vital. Criticality rankings further support transparent decision-making [3].

For example, condition-based monitoring can reduce failure risks while optimizing maintenance timing and lowering costs [4]. Techniques like Reliability-Centered Maintenance (RCM) can refine strategies by focusing on critical components [4]. This data directly supports the Strategic Asset Management Plan (SAMP), linking objectives to risk-based action plans [3].

Lifecycle and Cost Data

Lifecycle and cost data bridge your asset register with financial planning. This includes remaining useful life estimates, historical maintenance costs, and CAPEX/OPEX forecasts – key elements for informed investment decisions.

- Remaining useful life estimates guide capital expenditure planning by predicting when assets will need replacement. These estimates rely on condition data, deterioration trends, and past performance [7].

- Historical maintenance costs – covering labor, materials, and unplanned expenses – help forecast future financial needs with greater accuracy [7].

- CAPEX and OPEX forecasts should align with the planning horizon outlined in your SAMP. Scenario planning, like comparing run-to-failure against proactive replacement strategies, supports strategic decision-making.

Compliance and Sustainability Data

This category ensures your register aligns with regulatory and environmental goals. It includes compliance records, energy and emissions data, and sustainability certifications.

- Regulatory compliance records track inspections, permits, and certifications, ensuring audit readiness and preventing compliance gaps.

- Energy and emissions data monitor resource use and environmental impact, aiding sustainability reporting and identifying efficiency opportunities.

- Sustainability certifications (e.g., LEED, BREEAM, Energy Star) highlight environmental commitments and may influence investment priorities.

How to Structure and Organize Asset Data

A properly structured asset register is crucial for effective decision-making at all levels. The 2024 update to ISO 55001 introduced Clause 4.5, emphasizing the need for a framework that connects data from individual components to overarching business goals [9]. This approach ensures that operational details feed into executive strategies, creating a clear link between day-to-day operations and long-term outcomes.

Creating a Hierarchical Asset Data Structure

Think of your asset data as a pyramid with three distinct levels. At the top is the Strategic Asset Management Plan (SAMP), which outlines portfolio-wide performance targets and defines acceptable risk levels. The middle layer consists of Asset Management Plans (AMPs), which transform those high-level goals into tactical plans for specific asset categories, addressing lifecycle costs and reliability objectives through risk-based planning. At the base are operational activity plans, which focus on component-level details like maintenance history, condition ratings, and predictive data.

ISO 55001:2024 emphasizes the importance of this hierarchy, ensuring alignment between SAMP, AMPs, and operational plans. As ISO/TC 251 clarifies:

"The SAMP, which articulates asset management objectives, was previously misunderstood, the current version of ISO 55001 changes this" [1].

The revised standard positions the SAMP as the bridge between business goals and the specific data fields within your asset register.

To implement this structure effectively, avoid forcing assets into a single vertical hierarchy. Instead, create multiple horizontal views – organized by business unit, location, system, and asset type. For example, an HVAC system may span various business units. By organizing data this way, you can generate reports tailored to different stakeholder needs, whether focused on financial outcomes or operational performance.

Virtual assets are another key element. Grouping physical components into functional systems – like combining pumps, valves, and controls into a single "Chilled Water System" – enables performance tracking at the system level, aligned with the service-level objectives in your AMPs. This approach not only improves data quality but also lays the foundation for centralized data management.

Centralizing and Validating Asset Data

Once your hierarchical structure is in place, centralizing asset data becomes essential for compliance with Clause 7.6. This clause now requires "data and information specifications", along with a formal plan for collecting, integrating, improving, and sharing data [9]. Relying on disconnected spreadsheets can compromise both data quality and governance.

Centralizing asset data ensures compliance with ISO 55001 while maintaining long-term accessibility and portability. Even if a third party manages your data, retaining ownership is critical.

Regular validation is equally important. Implement change control processes to track updates and modifications. Automated quality checks can flag issues like missing fields, outliers, or inconsistent values. Additionally, conducting periodic sample surveys of asset groups helps monitor data quality over time. These measures not only keep your asset register ready for audits but also support the predictive actions required by Clause 10.3 of the 2024 standard [9].

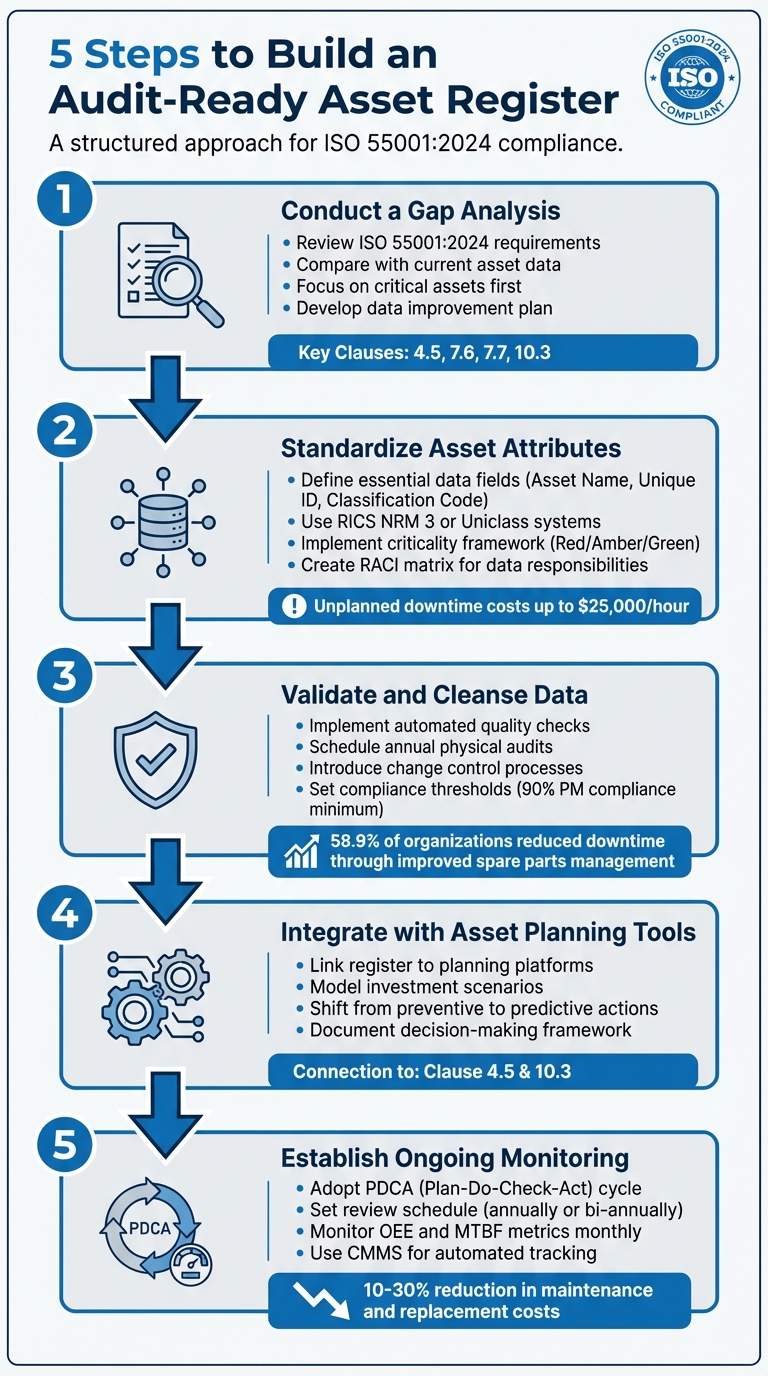

5 Steps to Build an Audit-Ready Asset Register

5 Steps to Build an ISO 55001-Compliant Asset Register

Creating an ISO 55001-compliant asset register is less about crafting a flawless document in one go and more about building a system that evolves with your organization while meeting audit standards from the start. Here’s how to approach it step by step.

Step 1: Conduct a Gap Analysis

Start by reviewing the requirements of ISO 55001:2024 and comparing them with your current asset data. Focus on these key areas:

- Does your asset register support decision-making and align with value criteria as outlined in Clause 4.5 [11]?

- Is it equipped to handle Predictive Action under Clause 10.3 by capturing data on potential failures and intervention points [11]?

- Do the current attributes meet the specifications for data and information required by Clause 7.6 [11]?

- Are processes in place to document tacit knowledge – expertise held by individuals – as required by Clause 7.7 [11]?

"Data and Information without context, insight and experience are of little value. The new section on Knowledge reminds organizations that tacit knowledge in individuals supports organizational knowledge." – ISO/TC 251 Committee [1]

Focus on critical assets first to achieve early compliance successes. A phased approach is much more manageable than overhauling your entire register at once. Use the findings from your gap analysis to develop a data improvement plan, which will guide you in standardizing asset attributes.

Step 2: Standardize Asset Attributes

Define essential data fields for all assets, including Asset Name, Unique ID, System/Element Group, Classification Code, and Asset Criticality [6]. Use established classification systems like RICS NRM 3 or Uniclass to maintain consistency. For maintenance alignment, consider SFG20 codes, which connect asset types to standard maintenance schedules [6].

Create a clear framework for ranking asset criticality, such as Red/Amber/Green or High/Medium/Low, to streamline resource allocation and risk management [6][12]. Unplanned downtime can cost up to $25,000 per hour [12], so this step is crucial. Additionally, set up a RACI matrix to clarify roles and responsibilities for data entry and validation [12].

Step 3: Validate and Cleanse Data

To ensure your data is accurate, implement automated quality checks and schedule annual physical audits [12]. This step is particularly important for spare parts inventory. In fact, 58.9% of organizations that successfully reduced unplanned downtime costs credit improved spare parts management [12].

"It is good to see that there is now an explicit requirement to focus on data quality improvement in ISO 55001:2024. This is something that was missing from the 2014 standard." – Sandy Dunn, Director, Assetivity [11]

Introduce change control processes with version control to keep an audit trail of updates [12]. Set compliance thresholds – investigate immediately if Preventive Maintenance compliance drops below 90% or if downtime exceeds pre-set targets [12]. Once your data is clean, integrate it with planning tools for a more comprehensive analysis.

Step 4: Integrate with Asset Planning Tools

Link your asset register to planning platforms like Oxand Simeo™. This step transforms your register into a dynamic tool that supports decision-making frameworks as required by Clause 4.5 [11]. Integration allows you to model investment scenarios, analyze lifecycle costs, and weigh maintenance versus replacement strategies.

Ensure the integration supports a shift from preventive to predictive actions. Clause 10.3 of the 2024 standard emphasizes the need for data on potential failures and optimal intervention points to maximize value [11]. Your tools should leverage condition data, performance trends, and risk profiles to anticipate issues before they arise.

"The SAMP [Strategic Asset Management Plan] must now contain the asset management decision-making framework… this means that the decision-making framework must also be formally documented." – Sandy Dunn, Director, Assetivity [11]

Step 5: Establish Ongoing Monitoring and Updates

Adopt the PDCA (Plan-Do-Check-Act) cycle for continuous review [13][14]. Set a specific review schedule – annually or every two years – and assign responsibility to a designated asset management owner [12]. Regular audits can verify asset matches and capture the tacit knowledge of staff [12][13].

The 2024 revision highlights the importance of individual expertise in Clause 7.7, recognizing its role in organizational knowledge and competitive advantage [14]. Use Computerized Maintenance Management Systems to automate tracking of maintenance history, spare parts usage, and asset condition, reducing manual entry errors [12][15].

Monitor key metrics like Overall Equipment Effectiveness (OEE) and Mean Time Between Failures (MTBF) monthly to spot performance trends and adjust risk profiles [12]. This ongoing monitoring ensures your register stays audit-ready while enabling data-driven decisions that can reduce maintenance and replacement costs by 10% to 30% [4].

Common Mistakes and How to Prioritize Data Collection

Avoiding mistakes in asset registers is crucial for meeting ISO 55001 standards, managing risks, and ensuring operational safety. One frequent misstep is relying on a single asset hierarchy. Instead, use multiple hierarchies – such as business, location, system, and asset levels – to improve reporting flexibility. Another common issue is the use of vertical spreadsheet formats for raw data. Since Microsoft Excel supports over 1 million rows but only 16,384 columns, a horizontal format (with assets in rows and attributes in columns) is better suited for large registers [10]. These structural errors can also make it harder to account for changes in asset conditions, which require ongoing updates.

A significant mistake is treating dynamic data as if it were static. Asset status and criticality need regular updates, and real-world insights should complement objective metrics. Lar English, Senior Asset Integrity Engineer at Gas Networks Ireland, highlights this issue:

"There is a widespread lack of properly structured asset registers among research and maintenance practitioners" [10].

Organizations also stumble when their asset management goals are not matched by adequate budgets or staffing. Additionally, gaps in data ownership – especially with third-party managed data – can lead to vulnerabilities [1]. Without clear contractual agreements, organizations may lack ownership rights or real-time access to critical data. To address these challenges, tools like the Mission Dependency Index (MDI) can help prioritize assets by assessing operational risks and the impact of potential failures. Another effective strategy is implementing change control processes. Documented procedures for adding, removing, or modifying assets – complete with change logs that capture reasons, requestors, and approvers – can provide much-needed structure [10].

Data Prioritization Table

When collecting data, focus on elements tied to ISO clauses and consider their implementation difficulty.

| Data Element | ISO Clause Link | Priority Level | Implementation Challenge |

|---|---|---|---|

| Unique Asset Identifiers | 4.3 | High | Low |

| Asset Criticality (Red/Amber/Green) | 6.1.2 | High | Low |

| Operational Status & Condition | 8.1 | High | Medium |

| Last/Next Maintenance Date | 9.1 | High | Low |

| Inspection Report ID | 4.2 | High | Medium |

| Serial Number, Make, Model | 7.6 | Medium | Low |

| Purchase Price, Replacement Cost | 8.1 | Medium | Medium |

| Energy Performance Metrics | 10.1 | Medium | Medium |

| Power Source, Refrigerant Type | 10.1 | Low | High |

Focus first on high-priority data, including asset identification, risk rankings, condition assessments, and maintenance schedules. These elements are critical for compliance and safety. Medium-priority data, like manufacturer details and financial information, support long-term planning but aren’t immediately essential. Low-priority metrics, such as sustainability details, can be addressed once the core asset register is fully established [10].

Conclusion

Creating an ISO 55001-compliant asset register goes beyond simply meeting certification requirements – it’s about empowering your organization to make smarter, more informed decisions. A well-organized register supports systematic risk management, helping you cut down on failure costs and move from reactive repairs to proactive, predictive maintenance that adapts to evolving conditions [1][4].

One of the key benefits is shifting the focus from upfront expenses to the Total Cost of Ownership (TCO). Since lifecycle operating costs often far exceed initial investments [5], having accurate data on maintenance costs, residual value, and replacement expenses becomes critical for long-term financial planning. Leveraging ISO 55001’s data-driven approach can lead to a 10–30% reduction in maintenance and replacement costs [4].

For organizations pursuing sustainability goals, the asset register becomes an essential tool. It allows you to track metrics like energy performance, material composition, and disposal impacts, enabling informed decisions that align with net-zero objectives and circular economy principles. This data helps justify sustainable asset replacements and extending asset lifespans [2][5][4].

The final piece of the puzzle is aligning your data priorities with strategic goals. As ISO TC251 emphasizes:

"Data and Information without context, insight and experience are of little value" [1]

This perspective is reflected in the 2024 standard, which introduces specific sections on data management and organizational knowledge [1]. Begin with key data elements such as unique identifiers, criticality ratings, condition assessments, and maintenance schedules. From there, expand your framework to ensure your asset management practices support both daily operations and long-term success.

FAQs

What essential data should be included in an ISO 55001-compliant asset register?

To create an asset register that aligns with ISO 55001 standards, you’ll need to gather and organize essential data that supports both effective management and informed decision-making. This includes:

- Asset identification details: Unique IDs, descriptions, and other identifiers.

- Location information: Where each asset is situated.

- Current condition: The physical and operational state of the asset.

- Performance metrics: Data on how the asset is performing.

- Lifecycle stage: Where the asset stands in its lifecycle.

- Risk assessments: Evaluations highlighting potential risks.

- Maintenance history: Records of past upkeep and repairs.

By structuring this information consistently and accurately, you’ll enable better risk-based planning, smarter investment decisions, and adherence to regulatory requirements. Keeping the data up-to-date ensures the register remains a powerful tool for both strategic and day-to-day operations.

How does predictive analytics improve asset data collection and management?

Predictive analytics improves how organizations gather and use asset data by helping them anticipate asset performance and maintenance requirements. This forward-thinking strategy aligns with ISO 55001 guidelines, promoting smarter, risk-aware decisions and better management of an asset’s lifecycle.

By examining key elements such as equipment condition, usage trends, and external factors, predictive analytics ensures asset registers remain accurate and up-to-date. This shift from reactive to proactive asset management boosts reliability, minimizes risks, and aids in making well-informed, long-term investment choices.

How can organizations maintain compliance with ISO 55001 standards over time?

To stay aligned with ISO 55001, organizations need to prioritize continuous improvement and take a proactive approach to managing risks. This means regularly reviewing and updating your asset management system to reflect changes in organizational goals, asset conditions, and regulatory requirements. Keeping your asset data accurate, relevant, and well-organized is also key for making informed decisions.

Periodic audits and gap analyses are essential for pinpointing areas that need attention and ensuring your processes match industry best practices. It’s equally important to secure leadership commitment and provide ongoing training for staff to integrate asset management principles into everyday activities. By promoting a culture of accountability and flexibility, organizations can manage risks effectively and take advantage of opportunities while maintaining ISO 55001 compliance.