Digital twins are transforming how businesses plan investments by simulating scenarios before committing resources. These virtual replicas of physical assets or systems use real-time data to help organizations predict outcomes, reduce risks, and align with environmental and financial goals. By modeling factors like carbon emissions, energy use, and maintenance needs, digital twins provide actionable insights for smarter decision-making.

Key Takeaways:

- What They Are: Digital twins are dynamic, data-driven models that mirror real-world assets or processes.

- Why They Matter: They help organizations meet sustainability targets, lower costs, and improve operational efficiency.

- How They Work: Using IoT sensors and AI, digital twins simulate "what-if" scenarios, enabling better planning without disrupting operations.

- Proven Results: Companies report 10%-25% savings on maintenance, extended asset lifespans, and measurable reductions in energy use and emissions.

Tools like Oxand Simeo™ simplify the process by centralizing data, forecasting performance, and testing investment strategies. Whether it’s retrofitting buildings, optimizing energy use, or meeting compliance requirements, digital twins offer a smarter way to plan for the future.

The Future of Digital Twin Technology

How Digital Twins Support Sustainable Asset Management

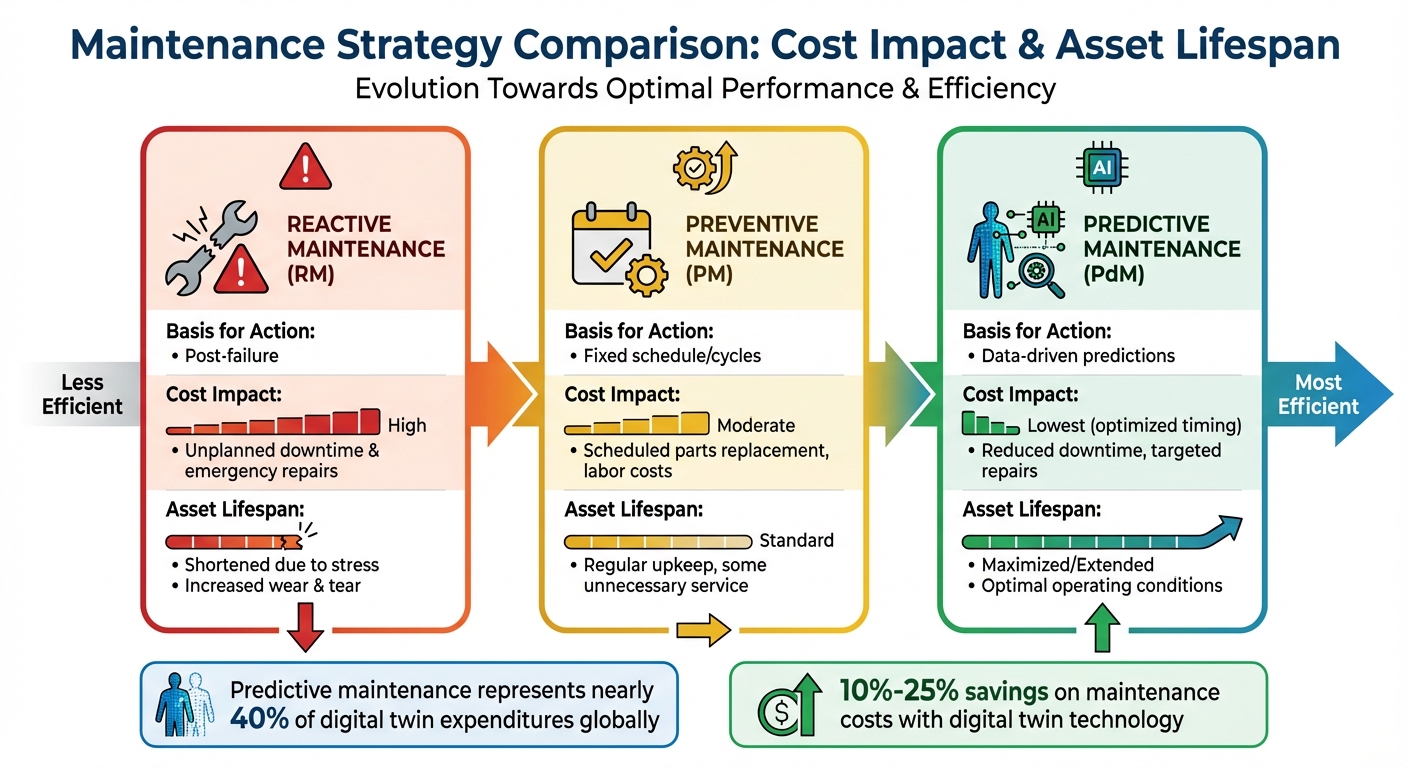

Maintenance Strategy Comparison: Reactive vs Preventive vs Predictive Digital Twin Approaches

Digital twins are transforming the way assets are managed by predicting environmental impacts, optimizing maintenance, and simplifying compliance with regulations. These capabilities not only help reduce risks but also improve long-term returns.

Predicting Carbon and Energy Impacts

Before making upgrades or retrofits, digital twins can simulate various scenarios to estimate CO₂ emissions and energy usage. For example, they allow you to compare the environmental effects of installing a new HVAC system versus upgrading insulation or testing renewable energy setups under different weather conditions. Considering that the buildings and construction sector accounts for about 36% of global emissions, this level of analysis is critical [6].

By combining IoT sensor data with Building Information Modeling (BIM), digital twins provide a dynamic view of energy performance that static models can’t match. They can identify issues like a cooling coil wasting energy – problems that might otherwise go unnoticed until costs start piling up [6].

Real-world examples highlight their potential. In Denmark, Sund & Bælt uses an AI-powered digital twin system built on the IBM Maximo Application Suite to manage massive bridges and tunnels, enabling predictive maintenance that extends infrastructure lifespans [5]. Similarly, in Australia, Downer Group has been monitoring over 200 trains since 2017 with its TrainDNA platform, using data to respond more effectively to weather and passenger demands while cutting the rail fleet’s carbon footprint [5].

Beyond energy and emissions, digital twins are also reshaping maintenance strategies.

Optimizing CAPEX and OPEX Over the Asset Lifecycle

Maintenance costs play a major role in the financial viability of sustainable investments. Digital twins shift the focus from reactive maintenance – fixing things only after they break – to predictive strategies that rely on performance data. This approach helps avoid unnecessary repairs and prevents costly failures. Globally, predictive maintenance represents nearly 40% of digital twin expenditures [3].

| Maintenance Strategy | Basis for Action | Cost Impact | Asset Lifespan |

|---|---|---|---|

| Reactive (RM) | Post-failure | High | Shortened due to stress |

| Preventive (PM) | Fixed schedule/cycles | Moderate | Standard |

| Predictive (PdM) | Data-driven predictions | Lowest (optimized timing) | Maximized/Extended |

For example, one major airport used a digital twin to model its ground operations, balancing the costs of hiring more staff against purchasing new equipment. The result? A 20% to 30% boost in operational efficiency [1].

"A digital twin provides a risk-based approach that uses centralized asset information to simulate operations based on historical data to predict future changes." – Tristan O’Gorman, Program Director, IBM Sustainability Software [5]

Digital twins also support "dig once" policies by identifying underground or structural work needs before a project begins. This minimizes community disruption and reduces the environmental impact of delays and rework [1]. In the European Union, where 85% of buildings were constructed before 2001 and are expected to remain in use for decades, digital twins could play a key role in retrofitting efforts [6].

By refining maintenance and planning, digital twins not only save money but also simplify compliance with sustainability goals.

Meeting Compliance and ESG Reporting Requirements

As sustainability regulations grow stricter, ESG reporting has become a time-consuming task for many organizations. Digital twins simplify this process by consolidating data on a single platform. They can track Scope 1, 2, and 3 emissions across supply chains and portfolios, generating reports that align with frameworks like the Envision Sustainable Infrastructure Framework [2].

Take New York City as an example. Local Law 97 imposes emissions caps on buildings over 25,000 square feet, impacting more than 40,000 structures starting in 2024 [7]. With buildings responsible for nearly 70% of the city’s emissions [7], compliance is essential. Digital twins can establish a baseline for carbon emissions and simulate the effects of retrofits, helping property owners meet these requirements without guesswork.

Smart buildings equipped with digital twin technology have reported energy savings of up to 30% through optimized HVAC and lighting systems [8]. Broader adoption could cut carbon emissions by 7.5 million tons by 2030 [9]. A survey of 800 organizations even found that 57% view digital twins as a key tool for managing ESG initiatives effectively [9].

"Digital twins can unlock more holistic sustainability outcomes when integrated from the earliest planning stages." – Institute for Sustainable Infrastructure [2]

In Australia, the Victoria State Government launched its "Digital Twin Victoria" program in June 2024. By combining data and spatial technologies, this initiative creates a digital replica of physical and social infrastructure. The goal? To build more resilient communities and improve disaster response through better visualization and data-driven planning [1].

How to Build and Use Digital Twins with Oxand Simeo™

Creating a digital twin doesn’t have to start from scratch. With Oxand Simeo™, you can transform existing data – whether it’s from spreadsheets, systems like SAP or Maximo, or BIM models – into actionable investment plans. These plans help balance costs, risks, and carbon goals. Here’s a simple three-step guide to centralize your data, set predictive models, and simulate scenarios.

Step 1: Centralizing Asset Data with Simeo Inventory

A reliable digital twin starts with clean, organized data. Simeo Inventory brings together asset information from various sources, like spreadsheets, CMMS exports, BIM models, and IoT sensor feeds, using REST and GraphQL APIs [11]. For on-the-ground data collection, the Simeo Go mobile app allows teams to conduct inspections in real time, complete with photos and standardized scoring. This method is 50% faster than outdated paper-based systems [11], eliminating the errors that often come with manual data entry.

"We needed a tool that would allow us to consolidate the fragmented data we had and project it in a way that could be clearly presented to our elected officials, who are the decision-makers." – Chief Executive Officer (General Director of Services) [13]

Within just two weeks of importing your data, you can launch multi-year investment scenarios [11]. This creates a single, trustworthy data source that all stakeholders can rely on, setting the stage for accurate performance forecasting.

Step 2: Setting Up Predictive Models and Sustainability Metrics

Once your asset data is centralized, Oxand Simeo™ uses its extensive database of 10,000 aging and energy laws and 30,000 maintenance actions to project asset wear and energy consumption [11]. The platform’s Energy Performance and Carbon Footprint Reduction Module provides detailed calculations, showing specific kWh and greenhouse gas savings for every maintenance or modernization action [11].

This precision helps you prioritize interventions that deliver the most impact within your budget. For instance, one public sector portfolio reduced its maintenance backlog by 27% while saving $4.4 million in energy costs across 66 buildings during the first budget cycle [11]. By moving away from generic age-based schedules, you can time interventions more effectively, extending asset life and shrinking your carbon footprint.

Step 3: Running ‘What-If’ Scenarios for Investment Planning

The Scenario Simulator allows you to test different investment strategies under real-world constraints, such as budgets, risks, energy targets, and carbon limits [11][13]. You can compare a "business-as-usual" approach with a "low-carbon" scenario to identify the most cost-effective way to meet your sustainability goals.

| Oxand Simeo™ Tool | Function | Contribution to Sustainability |

|---|---|---|

| Simeo Go App | Collects field data and inspections | Provides accurate data for energy and carbon modeling |

| Aging & Energy Laws | Forecasts asset degradation with AI | Identifies optimal times to reduce energy waste |

| Carbon Reduction Module | Calculates kWh and GHG savings | Delivers measurable metrics for ESG reporting |

| Scenario Simulator | Tests investment strategies | Maximizes ROI while meeting carbon constraints |

| Dynamic Planner | Adjusts plans in real time | Keeps goals aligned with changing budgets and conditions |

The Dynamic Planner adds flexibility, allowing you to adjust scenarios with simple drag-and-drop tools. If field conditions or budgets shift, you can recalibrate your plan instantly without starting over [11]. This keeps your digital twin up-to-date and aligned with real-world needs.

"Simeo directly integrates energy and CO₂ measurements into investment plans, allowing you to see which maintenance or modernisation actions will achieve the required savings within budget and risk limits." – Oxand [11]

Organizations that adopt this approach have reported an average 15% reduction in carbon emissions [10] and up to a 30% decrease in total ownership costs [11][12]. The platform also simplifies compliance by generating audit-ready reports for ISO 55000 and CSRD/ESRS standards, cutting report preparation time by 70% [11].

sbb-itb-5be7949

Measured Results: Outcomes from Digital Twin Implementation

The results show how digital twins play a key role in supporting risk-based asset investment strategies, ensuring better long-term outcomes.

Cost Savings and Extended Asset Lifespans

Organizations using digital twin technology for asset management consistently report 10% to 25% savings on maintenance costs. For instance, in May 2024, a global energy company reported a $500 million NPV improvement after leveraging digital twin simulations to optimize operations at a renewable ammonia plant [4].

Companies like Sund & Bælt and Downer Group have also seen clear benefits, including longer asset lifespans and more accurate maintenance schedules through predictive analysis and inspections [5].

"Digital twins have the potential to improve capital efficiency, accessibility of services, and operational performance of public sector investments by 20 to 30 percent." – McKinsey [1]

Switching to predictive maintenance has led to annual productivity increases of 3% to 5%, all while cutting operational costs [3]. This approach not only reduces expenses but also ensures assets perform better over time, giving decision-makers the confidence to plan for the future with greater certainty.

Beyond financial savings, digital twins are transforming how organizations manage energy use and reduce emissions.

Carbon and Energy Reductions Across Portfolios

In addition to cost benefits, digital twins are helping organizations reduce energy consumption and carbon emissions. The technology delivers measurable environmental gains. For example, in April 2025, optimized motor drive operations prevented the use of 535,526 tons of coal in just two weeks, while automated LED controls cut classroom energy consumption by 60% [14][15]. These results are crucial, especially since buildings are responsible for about 40% of global energy use [15].

"Integrating Digital Twins into building management can result in energy savings of up to 30%." – MDPI [14]

The broader impact is striking. For example, digital twins are projected to reduce municipal waste management costs by 30% to 35% by 2030 [14]. Across the U.S. manufacturing industry, the annual financial impact could reach $37.9 billion [3]. These examples highlight how simulation-based planning not only supports sustainability goals but also ensures strong financial performance across industries.

Conclusion: Making Confident Decisions with Digital Twins

Digital twins are changing the way organizations approach investment decisions, especially when it comes to balancing financial returns with sustainability goals. Instead of relying on guesswork, leaders can now test multiple scenarios and model strategies to determine the best course of action – all without taking on unnecessary risk [1][4]. This data-driven approach replaces assumptions with solid evidence, helping organizations align their financial objectives with environmental responsibilities.

By simulating outcomes with precision, digital twins provide measurable improvements in cost management and operational efficiency. Acting as a "single source of truth", this technology enhances transparency and helps identify potential challenges before they become costly problems [4]. For example, adopting a "dig once" policy – a strategy made possible by digital twin insights – reduces unnecessary expenses and minimizes delays, offering a level of assurance that static models simply can’t deliver [1].

"Digital twins – which can simulate a physical plant from the planning stage before it is built to the end of its lifetime – could help reduce the risks of investment, save costs, and speed up project timelines." – Nas Andriopoulos, Consultant, McKinsey [4]

Tools like Oxand Simeo™ take this a step further by centralizing asset data, running predictive models, and simulating investment scenarios under real-world constraints like budget, energy use, and carbon emissions. This approach consistently delivers 10% to 25% savings on maintenance costs, extends asset lifespans, and lowers emissions. With the digital twin market projected to grow at an impressive 36.3% compound annual growth rate through 2030 [5], it’s clear that adopting this technology isn’t just a forward-thinking move – it’s becoming a necessity to meet regulatory demands and stakeholder expectations.

The ability to make confident, sustainable investments starts with understanding your assets, forecasting their future performance, and testing scenarios before committing resources. Digital twins bring this capability to life, offering a level of scale and accuracy that traditional methods simply can’t match.

FAQs

How can digital twins help meet sustainability goals?

Digital twins are virtual replicas of physical assets, offering a powerful way to simulate and analyze different scenarios. These models can be used to evaluate carbon footprints, fine-tune energy consumption, and forecast maintenance needs, helping you make smarter decisions that align with sustainability goals.

With digital twins, you can cut down on waste, reduce emissions, and make better-informed investment decisions. This not only supports environmental objectives but also enhances long-term cost savings and ensures adherence to regulatory standards.

What are the main advantages of using digital twins for sustainable asset management?

Digital twins offer a virtual representation of physical assets, continuously updated with real-time data. This technology enables asset owners to simulate “what-if” scenarios, helping them explore various options before committing to costly investments. By forecasting factors like wear and tear, energy use, and carbon emissions, digital twins make it easier to pinpoint strategies that are both efficient and cost-effective.

The financial advantages are hard to ignore. For instance, they can help cut total ownership costs by as much as 30%, extend the useful life of assets, and reduce the chances of unexpected downtime. Beyond the numbers, digital twins centralize critical data, improve decision-making through scenario planning, and allow organizations to track carbon footprints – helping them stay aligned with sustainability goals and regulatory requirements.

In essence, digital twins drive smarter investment choices, lower risks, and deliver better long-term outcomes.

How do digital twins support regulatory compliance and ESG reporting?

Digital twins offer a dynamic, data-driven way to represent assets like buildings, bridges, or utilities, simplifying the process of meeting ESG (Environmental, Social, Governance) and regulatory requirements. By integrating real-time sensor data, they can calculate carbon emissions, ensure compliance with federal or state sustainability regulations, and produce clear, audit-ready reports. They also provide a transparent view of emission reductions, keeping investors, auditors, and stakeholders informed.

On top of that, digital twins leverage predictive analytics to anticipate maintenance needs and manage lifecycle costs. This helps minimize unplanned downtime and avoid potential regulatory penalties. By simulating different investment scenarios, decision-makers can weigh options that align cost-efficiency with sustainability goals, all while maintaining a documented record for ESG reporting. Essentially, digital twins transform compliance hurdles into practical, measurable strategies.