Predictive maintenance transforms how buildings operate by using real-time data and analytics to prevent equipment failures before they happen. Unlike reactive or fixed-schedule maintenance, this approach ensures systems like HVAC units, elevators, and electrical panels run smoothly, reducing disruptions and costs.

Key Benefits:

- Fewer Breakdowns: Reduces equipment failures by 70–75% and downtime by 35–45%.

- Cost Savings: Saves 8–12% compared to preventive maintenance and up to 40% compared to reactive methods.

- Improved Comfort: Ensures consistent heating, reliable elevators, and better air quality for occupants.

- Energy Efficiency: Cuts wasted energy by identifying inefficiencies early, lowering HVAC electricity use by ~10.6%.

Results:

- Organizations report 20–30% lower maintenance costs, 50% less unplanned downtime, and extended equipment lifespans by 20–36%.

- Tools like Oxand Simeo™ enable predictive maintenance without costly sensor installations, consolidating existing data to predict risks and optimize budgets.

Predictive maintenance is not just about fixing problems – it’s about preventing them, improving service quality, and delivering measurable financial and operational benefits.

Webinar: From Reactive to Predictive: The Next Evolution in Facility Operations

How Predictive Maintenance Improves Service for Occupants and Users

Predictive maintenance is reshaping the way buildings serve their occupants. By shifting from reactive fixes or rigid schedules to real-time data monitoring, facility managers can keep systems running smoothly. This approach offers three key benefits: fewer disruptions, safer and more comfortable environments, and better energy efficiency – all of which directly enhance the daily experience for users. Let’s dive into how predictive maintenance achieves these outcomes.

Reducing Disruptions and Downtime

Unplanned equipment failures cost industries a staggering $50 billion annually [8]. When an HVAC system fails or an elevator stops working, the impact goes far beyond inconvenience – it can grind operations to a halt. Predictive maintenance tackles this by using IoT sensors to monitor critical conditions like temperature, vibration, and pressure, catching potential issues before they spiral into major problems [1].

The financial savings are hard to ignore. Reactive maintenance calls can cost three times more – an extra $400 per call on average [1]. By scheduling repairs during off-peak hours, this approach reduces both expenses and disruptions for occupants.

Real-world examples highlight its effectiveness. A global chemical plant cut urgent maintenance tasks from 43% across 33 assets [10]. Similarly, a petrochemical facility detected compressor misalignment early, avoiding $600,000 in potential losses [10].

"Predictive maintenance tells you what needs attention, when it needs attention, and why – so you can proactively prevent breakdowns instead of reacting to them after the fact."

– CameraMatics [9]

Improving Safety and Comfort for Occupants

Safety and comfort are top priorities, and predictive maintenance plays a big role in addressing them. Companies using predictive technologies report a 27% boost in safety performance [2].

Take air filters, for example. Traditional replacement schedules often result in filters being changed too early or too late, which can compromise air quality. Predictive systems monitor differential pressure in real time, alerting technicians exactly when filters need attention – ensuring clean air without unnecessary disruptions.

Temperature control also gets a boost. AI-driven HVAC systems dynamically adjust settings to maintain consistent comfort, avoiding the fluctuations typical of reactive fixes. Occupancy sensors further enhance this by fine-tuning lighting and climate control based on real-time usage [1].

Trenitalia, Italy’s national train operator, provides a powerful example. By installing hundreds of sensors on 1,500 locomotives, the company reduced downtime by 5–8% and cut their $1.3 billion annual maintenance costs by 8–10%, saving about $100 million annually while improving on-time performance [2] [7].

Elevators and escalators also benefit from continuous monitoring. Enertiv, for instance, achieved a 50% reduction in major equipment failures and a 25% decrease in maintenance costs through predictive maintenance powered by IoT [4].

Improving Energy Efficiency and User Experience

Commercial buildings waste about 30% of their energy [6]. Predictive maintenance identifies inefficiencies – like refrigerant leaks, clogged filters, or valve issues – before they escalate into costly failures.

For instance, clogged air filters force fans to work harder, consuming more energy. Sensors monitoring differential pressure can alert technicians to clean or replace filters before this strain builds up [2]. Similarly, vibration analysis can catch early signs of problems in pumps or fans, such as worn bearings or misalignment [11].

IoT sensors also optimize energy use by tracking real-time occupancy. HVAC and lighting systems adjust automatically, ensuring energy isn’t wasted on empty spaces [1]. Analytics can even stagger the startup of heavy HVAC equipment, reducing peak energy demands [6]. These adjustments not only save money but also create a more comfortable environment for users.

A prime example comes from a Class A office tower in Riyadh’s King Abdullah Financial District. Using an AI model to analyze two years of building data, the facility saw unplanned outages drop by 47.6%, total downtime decrease by 41.3%, HVAC electricity consumption fall by 10.6%, and overall operating costs decline by 9.7% [12].

When systems run efficiently, they maintain stable temperatures, proper humidity levels, and good air quality – factors that directly improve the occupant experience. As Steve Segarra, CTO of Archibus-Serraview, puts it:

"Each year, utilities may cost $3 per square foot and space $30 per square foot, but the employees that occupy the space cost $300 per square foot… Investments that optimize the productivity of the workplace tend to yield a disproportionately high return on investment." [6]

How Oxand Simeo™ Enables Predictive Maintenance

For many organizations, the challenge lies in transforming existing asset data into actionable maintenance strategies. Oxand Simeo™ offers a data-driven solution that avoids the need for expensive sensor installations. Instead, it uses over 10,000 proprietary aging and energy algorithms alongside 30,000 maintenance actions to predict asset degradation and the costs of intervention – all based on existing data sources [13][14].

The platform organizes fragmented information from spreadsheets, CMMS systems, and BIM models into a structured, centralized database. It also simulates the optimal timing for maintenance compared to full replacement. For example, one Asset Director managing a public sector portfolio of 66 buildings achieved a 27% reduction in maintenance backlog and saved €4 million in energy costs during the first budget cycle, recouping the investment within that same period [13].

The implementation process is quick and efficient. Most organizations can begin creating multi-year investment scenarios within two weeks of importing their existing data [13]. The Simeo Go mobile app further speeds up field inspections by 50% compared to traditional paper methods, ensuring real-world conditions are quickly integrated into predictive models [13]. As one Head of Budget and Asset Valuation explained:

"We turned to Oxand because we needed a tool that would provide us with a predictive – not just corrective – view and help us manage our investments more effectively. Oxand stood out for its risk management capabilities." [14]

This integrated approach supports precise, risk-based planning, centralized asset management, and dynamic scenario modeling.

Risk-Based CAPEX/OPEX Planning

Traditional maintenance often relies on age-based replacements or reactive fixes after failures occur. Simeo™ changes this by predicting future risks and costs before they escalate [14]. This proactive approach can lower total ownership costs by up to 30% while stabilizing multi-year budgets [13].

The financial benefits go beyond immediate savings. By creating stable CAPEX and OPEX plans, Simeo™ eliminates the financial unpredictability associated with reactive maintenance. Facility managers can present well-supported investment plans to stakeholders, backed by quantitative data, making it easier to secure funding and align everyone on long-term goals [13][14].

Centralized Asset Data Management

Disorganized or fragmented data often hinders effective predictive maintenance. When asset information is scattered across spreadsheets, outdated CMMS systems, and incomplete BIM models, building an accurate maintenance strategy becomes nearly impossible. Simeo™ tackles this issue by consolidating all asset data into a single, unified database [13]. This "single source of truth" ensures every maintenance decision is based on accurate, up-to-date information.

As one CEO noted:

"We needed a tool that would allow us to consolidate the fragmented data we had and project it in a way that could be clearly presented to our elected officials, who are the decision-makers." [14]

This centralized approach offers practical advantages. For instance, managers can schedule major maintenance during non-peak times, such as school breaks, to reduce disruptions for occupants [16]. Interactive dashboards and maps provide instant visibility into safety risks, helping teams prioritize critical repairs, like addressing playground equipment or emergency systems [13]. The result? Faster response times and fewer interruptions for building users.

Scenario Simulations for Maintenance Planning

Balancing budget constraints, risk levels, and energy goals often feels like juggling competing priorities. Simeo™’s scenario simulator helps by letting you test different maintenance strategies under real-world limitations before committing resources [13][14]. The tool generates multiple investment scenarios, balancing CAPEX and OPEX over various timelines. It allows you to explore the impacts of deferring maintenance, accelerating energy upgrades, or tweaking spending to meet carbon reduction goals. The Energy Performance and Carbon Footprint Reduction Module quantifies energy savings and greenhouse gas reductions for each planned action, making it easier to identify investments that deliver both financial and environmental benefits [13].

The Dynamic Planner feature adds flexibility, enabling users to adjust actions manually without restarting the simulation [13]. With these tools, you can pinpoint when deferred maintenance risks becoming a critical failure – and take action to avoid it.

Many organizations see ROI within 6 to 12 months, often during the first budget cycle [13][14]. Additionally, Simeo™ can cut ISO 55000 audit preparation time by up to 70% by automatically generating compliant reports and audit trails [13]. This blend of financial returns and operational efficiency makes predictive maintenance practical for organizations that previously couldn’t justify investing in sensor-heavy infrastructure.

sbb-itb-5be7949

Measured Results of Predictive Maintenance on Service Quality

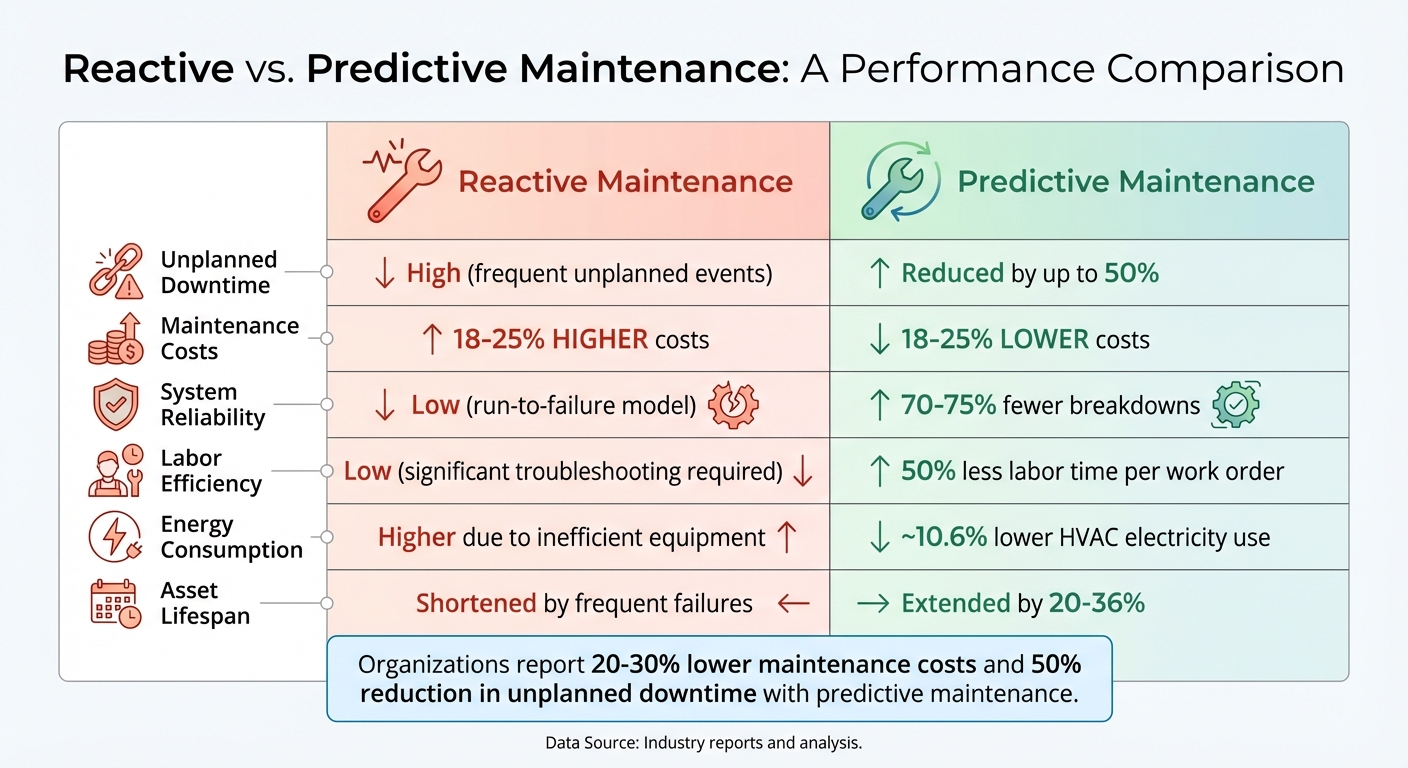

Reactive vs Predictive Maintenance: Cost and Performance Comparison

Measured Benefits and Cost Savings

Organizations that implement predictive maintenance report 18–25% lower overall maintenance costs and a 50% reduction in unplanned downtime [5]. This approach also reduces system breakdowns by 70–75% compared to traditional reactive methods [5].

By using condition-based monitoring, asset lifespans can increase by 20–36% [4]. For building owners and facility managers, this means fewer unexpected replacements and more stable budgets. In HVAC systems, specifically, predictive and preventive maintenance can yield an ROI as high as 545% [5].

Safety also sees a boost, with a 27% improvement in performance, as emergency repairs – often riskier – become much less frequent [2]. A great example comes from KONE, which revamped its IoT platform in October 2025 using AWS and AI-powered analytics to monitor 1.6 million pieces of equipment. The upgrade led to a 70% increase in proactive fault detection, 40% fewer customer-reported issues, and 40% fewer passenger entrapments [17]. Ashish Agrawal, KONE’s Chief Information Officer, highlighted the impact:

"The technology core we built on AWS is a backbone on which we can scale, innovate in the market, and differentiate ourselves in the best urban flow experience." [17]

Another example is a November 2025 study conducted in a large commercial office building in Riyadh. Using LSTM networks to analyze two years of building management data, the predictive approach cut unplanned outages by 47.6%, reduced total downtime by 41.3%, and lowered HVAC electricity use by 10.6%, resulting in a 9.7% drop in total operating costs [12]. Similarly, a 29-story office building in September 2022 saved over $16,700 annually on operating expenses and an additional $32,300 per year in repair costs by adopting IoT sensors and analytics. This also led to a 50% drop in major equipment failures [4].

Labor efficiency also improves dramatically. Transitioning from reactive to predictive maintenance cuts labor costs in half, as reactive work orders take twice as long to complete and cost about $400 more per call [18][3]. These measurable benefits highlight the clear advantages of predictive maintenance over reactive methods.

Comparison: Reactive vs. Predictive Maintenance

Here’s a side-by-side look at the key differences between reactive and predictive maintenance:

| Feature | Reactive Maintenance | Predictive Maintenance |

|---|---|---|

| Unplanned Downtime | High (frequent unplanned events) [5] | Reduced by up to 50% [5] |

| Cost | 18–25% higher maintenance costs [5] | 18–25% lower maintenance costs [5] |

| Reliability | Low; operates on a "run-to-failure" model [3] | 70–75% fewer breakdowns [5] |

| Labor Efficiency | Low; requires significant troubleshooting and travel [18] | 50% less labor time per work order [18] |

| Energy Use | Higher due to inefficient equipment [18] | ~10.6% lower HVAC electricity use [12] |

| Asset Lifespan | Shortened by frequent failures [4] | Extended by 20–36% [4] |

Reactive maintenance often results in costly, last-minute interventions, putting a strain on budgets and resources. Predictive maintenance, on the other hand, identifies potential problems early, allowing teams to address them during planned downtime. This not only minimizes disruptions but also leads to lower costs, improved service quality, and longer-lasting equipment. These measurable gains underscore how predictive maintenance elevates service standards for both facility managers and building occupants.

Steps to Implement Predictive Maintenance with Oxand Simeo™

Building a Complete Asset Data Foundation

To kickstart predictive maintenance with Oxand Simeo™, the first step is creating a reliable and unified asset database. Simeo’s Smart Data Import and APIs make it easy to consolidate legacy data from various sources like spreadsheets, CMMS exports (e.g., SAP or Maximo), BIM models, or IoT sensor feeds. This process allows you to establish a comprehensive inventory in just days, eliminating the need for lengthy hardware installations or manual processes [13].

Field teams can replace outdated paper-based inspections by using Simeo Go, a mobile app that syncs standardized data entries directly to the cloud. This ensures your asset inventory stays accurate and updated in real time. Organizations using Simeo Go report data collection speeds that are 50% faster compared to traditional methods [13]. Once your inventory is ready, Oxand’s extensive library of 10,000 aging and energy models predicts how key components will degrade over time, giving you a clear view of future maintenance needs [13].

Developing Predictive Models and Maintenance Plans

With your asset data in place, the next step is configuring predictive models. Simeo™ uses its database of 30,000 maintenance actions and cost benchmarks, combined with its aging models, to forecast risks before they escalate into failures [13] [14]. The platform’s scenario simulator lets you evaluate multiple investment strategies under different constraints, such as budget, risk tolerance, energy performance, and decarbonization goals. This helps you determine the most effective plan forward [14] [15].

The Dynamic Planner tool provides flexibility by allowing drag-and-drop adjustments to maintenance schedules and costs. For example, you can align disruptive work with school breaks or low-occupancy periods, reducing the impact on daily operations [16]. By focusing on high-risk areas, you can allocate resources where they’ll have the greatest impact. Most organizations using this approach see measurable results within 6–8 months [15].

To take your maintenance planning further, integrate energy efficiency and sustainability goals into your strategy.

Integrating Energy and Sustainability Goals

Oxand Simeo™ includes an Energy Performance and Carbon Footprint Reduction Module that calculates potential energy savings and greenhouse gas reductions for each maintenance action [13]. This feature allows you to design investment scenarios that balance decarbonization targets with budget and risk considerations, helping you identify the most cost-effective path to sustainability [13] [15].

The platform also supports compliance with ISO 55000 and generates reports aligned with the Energy Performance of Buildings Directive (EPBD) [13]. Instead of treating carbon metrics as a separate task, Simeo™ integrates CO₂ reduction trajectories directly into multi-year investment plans. This approach prioritizes areas like outdated HVAC and lighting systems, which often offer the greatest opportunities for cutting energy costs and emissions [16]. By adopting this integrated strategy, organizations can lower their total cost of ownership by up to 30% while meeting their sustainability goals [13] [15].

Conclusion

Predictive maintenance is a game-changer for protecting assets and improving service for occupants. By identifying potential issues 30–90 days before they occur, it helps you sidestep disruptions, safety hazards, and costly repairs – repairs that can cost 3–5 times more than routine maintenance [19]. The payoff? A more dependable, comfortable, and energy-efficient environment for everyone relying on your facilities.

These operational improvements also lead to impressive financial outcomes. Organizations that adopt predictive maintenance strategies often report 20–30% lower maintenance costs and 33% reductions in spare parts usage [19]. It allows for stable and predictable CAPEX and OPEX planning, eliminating the constant scramble to address emergencies. For example, Delta Air Lines leveraged AI-driven predictive maintenance through its APEX program, achieving annual savings in the eight-figure range and earning Aviation Week’s 2024 Innovation Award [19].

With Oxand Simeo™, these benefits are within reach – without the need for costly sensor installations. The platform uses 10,000 aging and energy performance algorithms and 30,000 maintenance actions to predict risks and costs based on your existing data [14]. You can even run scenario simulations to align your budget with sustainability goals and plan maintenance during low-occupancy periods. Most organizations begin seeing tangible results in just 6 to 8 months.

FAQs

What makes predictive maintenance different from reactive and preventive maintenance?

Predictive maintenance offers a smarter alternative to reactive and preventive maintenance by leveraging data-driven insights to manage assets more effectively. Reactive maintenance waits until equipment breaks down to address issues, which can lead to unexpected downtime, safety risks, and expensive repairs. Preventive maintenance, on the other hand, follows a fixed schedule to prevent failures but can result in unnecessary work and higher costs since it doesn’t consider the actual condition of the equipment.

With predictive maintenance, real-time data from sensors and IoT devices is used to continuously monitor how assets are performing. Advanced analytics then come into play, identifying potential issues before they escalate. This allows maintenance to be performed only when it’s truly needed. The result? Fewer disruptions, safer operations, longer asset lifespans, and more efficient use of resources – making predictive maintenance a forward-thinking choice over traditional approaches.

What financial advantages can predictive maintenance offer?

Predictive maintenance offers major financial advantages by cutting down on unplanned downtime, reducing expensive emergency repairs, and fine-tuning maintenance schedules. Facilities using predictive strategies often experience impressive results – downtime can drop by as much as 52.7%, and defects may decrease by up to 87.3%.

By tackling problems early, predictive maintenance extends the life of equipment, reducing replacement costs and boosting operational efficiency. This forward-thinking method ensures resources are allocated wisely, leading to better returns on investment and more dependable performance.

How does predictive maintenance improve safety and comfort for building occupants?

Predictive maintenance enhances both safety and comfort by catching potential problems before they escalate into major issues. With the help of IoT sensors and smart monitoring systems, facility managers can keep an eye on critical factors like temperature, vibration, and equipment performance. This allows them to predict and address malfunctions ahead of time. The result? Fewer unexpected breakdowns, consistent indoor conditions, and a safer environment for everyone.

Take HVAC systems, for instance. Spotting issues early ensures steady temperature control and better air quality, which means a healthier and more comfortable space for occupants. Plus, scheduling maintenance at the right time reduces disruptions, extends the life of essential systems, and lowers the chances of expensive emergencies or safety hazards. By adopting predictive maintenance, buildings become more dependable, efficient, and better suited to the needs of their occupants.

Related Blog Posts

- Predictive vs Reactive Maintenance: Cost Analysis Guide

- Predictive Maintenance for Asset Management (Infrastructure and Real Estate) is critical – use the web site the web site:https://theiam.org

- How predictive maintenance (without IOT and real time) brings value to infrastructure and building asset owners

- Energy Savings and Emissions Reduction: The Hidden ROI of Predictive Maintenance