Preparing for ISO 55001 audits can be overwhelming, but digital platforms like Oxand Simeo™ simplify the process by centralizing data, automating documentation, and improving risk visibility.

Belangrijkste opmerkingen:

- Save Time: Audit prep time can drop by up to 70% by automating reports and consolidating data.

- Reduce Errors: Centralized systems eliminate scattered spreadsheets and manual processes.

- Improve Compliance: Real-time dashboards and predictive tools ensure readiness for audits while cutting administrative workload by 40–60%.

- Proactive Management: AI-driven models forecast risks and help align maintenance plans with compliance standards.

This shift allows you to focus less on paperwork and more on managing assets effectively.

Internal Audits in ISO 55001

Common Problems in ISO 55001 Internal Audits

ISO 55001 audits often reveal hurdles that make data centralization and timely reporting difficult, emphasizing the growing importance of digital tools. When data is scattered and documentation relies on manual processes, the audit process can become an overwhelming task for asset managers and compliance teams.

Scattered Data Across Multiple Systems

Asset information is often spread across different systems – maintenance logs in one place, risk assessments in another, and financial data somewhere else. This fragmentation forces teams to manually gather and piece together data, which not only wastes time but also increases the likelihood of errors. Without a centralized asset register, it’s nearly impossible to maintain a single, reliable source of truth. Traditional systems that lack built-in data analytics only add to the challenge, leaving asset managers to navigate a maze of disconnected information.

Manual Reporting and Documentation

Manually compiling audit reports is a tedious and error-prone process. Asset managers frequently spend hours pulling data from spreadsheets, cross-checking paper checklists, and filling out audit templates. This “spreadsheet chaos” disrupts workflows and increases the chance of mistakes, ultimately weakening the quality of audit evidence. On top of that, manual methods often rely on outdated indicators, making it harder to shift from reactive to proactive risk management. By comparison, digital audit tools have been shown to improve data quality by 63% and boost productivity by 27% [4].

Time Constraints and Compliance Risk

Time pressure is another major challenge, turning audit preparation into a significant bottleneck. Manual processes leave teams scrambling to locate maintenance or inspection records, which raises compliance risks and makes it harder to meet audit deadlines. The time spent digging through siloed systems for asset histories also limits the ability to focus on proactive, risk-based decisions.

These challenges make a strong case for adopting digital solutions that can simplify and optimize audit workflows.

How Digital Platforms Simplify ISO 55001 Audits

Digital platforms are transforming the way ISO 55001 audits are conducted by offering streamlined, automated, and highly organized solutions. Instead of manually gathering data from scattered sources, asset managers can now rely on centralized systems that consolidate information, generate compliant documentation, and provide real-time insights into asset performance and risks.

Gecentraliseerd beheer van activagegevens

Simplifying audits begins with bringing all asset data into one unified system. Platforms like Oxen en Simeo™ do just that by consolidating information from spreadsheets, CMMS exports (e.g., SAP of Maximo), BIM models, and IoT sensor feeds into a single, reliable asset inventory. Field teams can use mobile tools like Simeo Go to carry out on-site inspections, syncing their findings directly to the cloud. This ensures that asset records stay accurate and up to date.

Additionally, smart APIs such as REST en GraphQL allow seamless integration of legacy systems with the central platform, effectively breaking down data silos. The result? A trustworthy, centralized source of truth for auditors that can cut ISO 55001 audit preparation time by as much as 70% [3].

Automated Documentation and Traceability

Gone are the days of manually compiling audit reports. Digital platforms now automate the process, logging every asset event with timestamps and user identities. Built-in ISO 55001 checklists further enhance efficiency by auto-generating audit-ready reports that meet compliance standards [3].

"Simeo integrates ISO 55001 checklists, automatically generates audit trails from investment plans and produces audit-ready reports, reducing preparation time by up to 70%." – Oxand [3]

AI tools take it a step further, scanning for gaps in documentation and auto-generating complete asset histories [5]. This level of automation can reduce administrative work by 40–60% within just six months of adoption [1].

With automated documentation in place, these platforms also enable real-time integration, which is key to proactive risk management.

Real-Time Data Integration and Risk Visibility

By continuously updating asset inventories with real-time field data, predictive risk models, and performance metrics, digital platforms move audits from being reactive to predictive. Instead of relying on outdated snapshots, asset managers gain immediate insights into risks and compliance. Platforms like Oxen en Simeo™ incorporate science-based aging laws and maintenance models to forecast asset degradation, giving auditors a forward-looking view of potential risks rather than just historical data [3].

Interactive dashboards further simplify the process by offering clear visualizations of asset conditions, energy performance, and renewal priorities. Asset managers can simulate various investment scenarios while balancing budgets and risks, providing decision-makers with evidence that aligns with ISO 55001 requirements. This ensures that organizations are always prepared for audits, with compliance baked into their daily operations.

How to Use Oxand Simeo™ for ISO 55001 Audits

Getting started with Oxen en Simeo™ is quick and efficient – it can be up and running in less than two weeks by importing your existing data [3]. The platform integrates seamlessly with your current systems, whether you’re using spreadsheets, CMMS exports, BIM models, or IoT feeds, turning scattered information into clear, audit-ready evidence.

Step 1: Build a Centralized Asset Inventory

A solid ISO 55001 audit begins with a well-organized and comprehensive asset register. Simeo-inventaris helps consolidate all your asset data into a single, structured system, complete with asset breakdown structures, required data fields, and criticality assessments [2]. Field teams can use Simeo Go to inspect assets and capture standardized data, eliminating the need for outdated spreadsheets [3]. This tool speeds up data collection by 50% by replacing paper-based processes [3].

You can bulk upload legacy data or connect live systems through REST and GraphQL APIs [3]. This creates a centralized, reliable source of truth that ensures consistency and accuracy across your portfolio – exactly what auditors look for [3].

Step 2: Automate Audit-Ready Reporting

Once your asset inventory is centralized, the next step is to streamline your reporting. Oxand Simeo™ simplifies this process by automatically generating documentation and traceable evidence trails directly from your investment plans [2]. With built-in ISO 55000 checklists, the platform can create audit-ready reports in just one click using Qlik-powered dashboards [3].

The platform’s database includes 10,000 proprietary aging and energy laws and 30,000 maintenance actions, providing a technical framework for your investment decisions [3]. This allows you to precisely time interventions and document the reasoning behind your maintenance strategies – key elements auditors require during an ISO 55001 review [3]. De Dynamische Planner feature also lets you adjust costs and schedules in real time, ensuring your documentation reflects the current state of your asset portfolio [3].

Step 3: Simulate Scenarios for Compliance Evidence

To strengthen your compliance evidence, Oxand Simeo™ enables you to test various scenarios. The Scenario Simulator lets you model budget, risk, energy, and carbon constraints [3]. You can evaluate different investment strategies over 5, 10, or even 20 years, visualizing how each approach impacts your portfolio’s risk and compliance levels. This provides board-ready evidence of ISO 55001-compliant strategies [3].

Rather than relying on outdated age-based replacement schedules, the platform supports risk-based prioritization. This approach quantifies how different strategies affect asset reliability and safety [6][2]. It also provides forward-looking evidence, demonstrating to auditors not only your past actions but also how you’re proactively managing future risks.

As one client shared, the platform transformed their management approach:

"We needed a tool that would provide us with a predictive – not just corrective – view and help us manage our investments more effectively. Oxand stood out for its risk management capabilities." – Head of Budget and Asset Valuation Department [6]

sbb-itb-5be7949

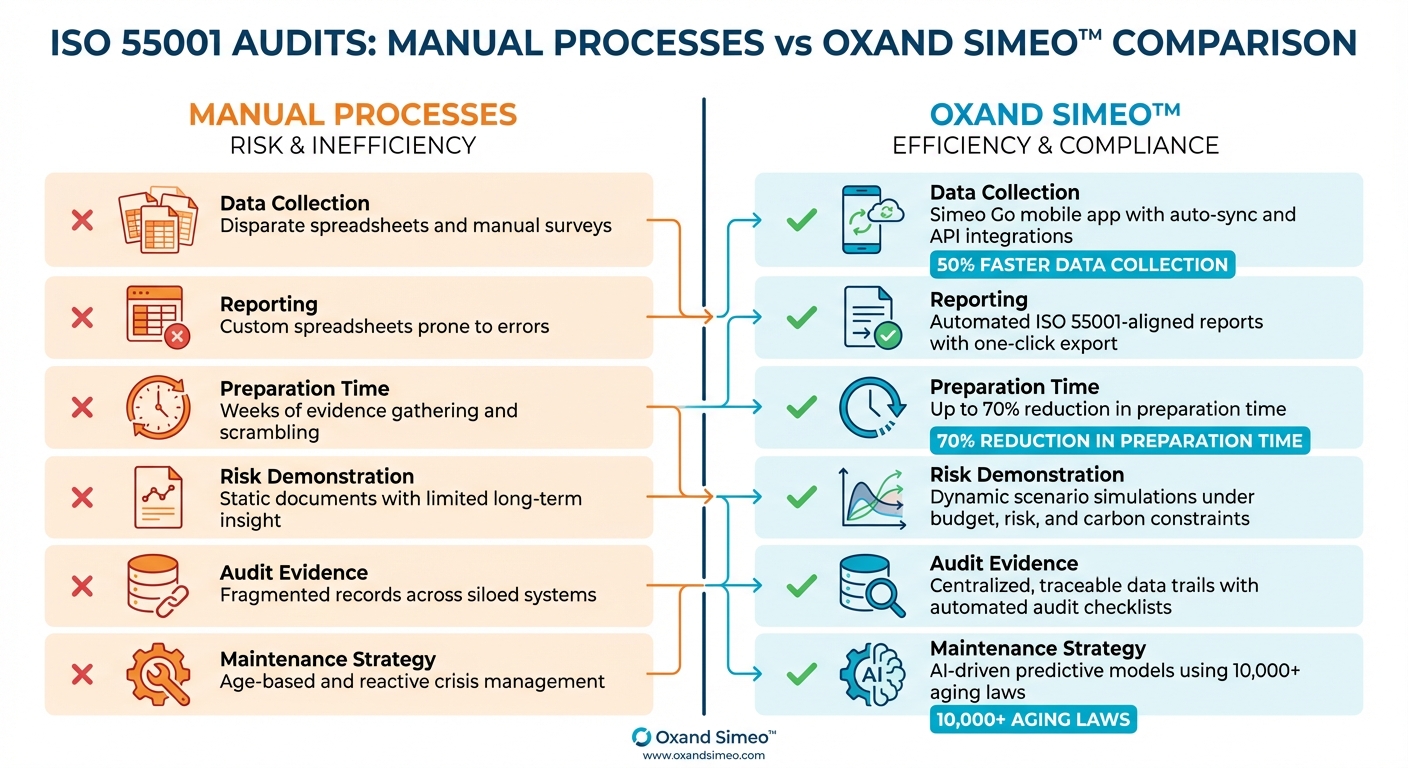

Manual Processes vs. Oxand Simeo™

Manual vs Digital ISO 55001 Audit Processes Comparison

When it comes to preparing for an ISO 55001 audit, the tools and methods you use can make or break the process. Traditional, manual approaches often lead to chaos – time-consuming data collection, errors, and incomplete documentation. Oxand Simeo™ steps in to change the game entirely, simplifying and automating the most challenging parts of the process.

Instead of spending weeks pulling together scattered data from multiple systems, Oxand Simeo™ centralizes everything into one platform. Field teams can use the Simeo Go mobile app to capture inspection data in real time – cutting the time spent on data collection by 50% compared to paper methods. And when it’s time to generate reports, the platform creates ISO 55001-aligned documents with just one click, reducing preparation time by up to 70% [3].

Oxand Simeo™ doesn’t stop at making things faster – it also makes them smarter. By replacing outdated, static maintenance plans with AI-powered predictive models (based on 10,000 proprietary aging laws), it shifts the focus from reactive fixes to proactive risk management [3]. For example, Simeo helped reduce maintenance backlogs by 27% and saved €4 million in energy costs across 66 buildings during a single budget cycle [3].

Here’s how manual processes stack up against Oxand Simeo™:

Comparison Table

| Aspect | Manual Processes | Oxen en Simeo™ |

|---|---|---|

| Gegevensverzameling | Disparate spreadsheets and manual surveys | Simeo Go mobile app with auto-sync and API integrations (50% sneller) |

| Reporting | Custom spreadsheets prone to errors | Automated ISO 55001-aligned reports with one-click export |

| Preparation Time | Weeks of evidence gathering and scrambling | Tot 70% reduction in preparation time |

| Risk Demonstration | Static documents with limited long-term insight | Dynamic scenario simulations under budget, risk, and carbon constraints |

| Audit Evidence | Fragmented records across siloed systems | Centralized, traceable data trails with automated audit checklists |

| Onderhoudsstrategie | Age-based and reactive crisis management | AI-driven predictive models using 10,000+ aging laws |

Source: Oxand Simeo™ product information [3].

Switching from manual methods to Oxand Simeo™ is about more than just saving time. It’s about creating a transparent, streamlined process that builds confidence when regulators come knocking. With automated tools and predictive insights, you’re not just meeting audit requirements – you’re setting a new standard for efficiency and readiness.

Best Practices for Using Digital Platforms in Internal Audits

To truly benefit from digital platforms during ISO 55001 audits, it’s not just about the tools you choose – it’s about how effectively you use them. A smooth audit process often depends on maintaining accurate data, staying proactive, and ensuring your evidence is always prepared.

Maintain Data Quality and Centralization

An accurate asset inventory starts with reliable data. Mobile apps like Simeo Go can transform on-site inspections into standardized, structured records, eliminating the guesswork and errors that come with handwritten notes. By integrating live systems through APIs (REST and GraphQL), you can create a single, reliable data source for your audits [3]. Clearly defining your asset breakdown structure, including criticality levels, ensures that audit efforts focus on the most vulnerable components. Additionally, platforms built on ISO 27001-certified infrastructure with AES-256 encryption keep your data secure throughout the entire process [3].

Use Real-Time Dashboards

Real-time dashboards are a game changer, shifting your approach from reacting to problems to preventing them. Instead of waiting for annual reports to uncover compliance issues, these dashboards let you continuously monitor key metrics like preventive maintenance compliance, energy usage, and emissions [1]. For instance, if preventive maintenance compliance drops below 90%, you can address it immediately – long before an auditor flags it [7]. Automated audit trails, which log every asset change with timestamps and user identities, make it easy for auditors to trace asset histories in seconds [1]. Organizations with formal asset governance and real-time visibility have seen operating expenses drop by 12–18% [1]. This kind of proactive oversight also strengthens risk management by keeping condition models up to date.

Keep Risk and Condition Models Updated

Static models quickly lose relevance. Using mobile inspection apps and predictive models that apply science-based aging laws allows you to keep risk and condition data current. Tools like Oxand Simeo™ leverage over 10,000 proprietary aging and energy laws to provide precise forecasts of asset degradation [3]. Regularly updating these models not only sharpens maintenance strategies but also simplifies audit preparation by presenting real-time asset health. This approach can reduce total ownership costs by up to 30% through well-timed interventions, while also serving as robust audit evidence – eliminating the stress of last-minute documentation [3].

Conclusie

Digital platforms are reshaping the way organizations approach ISO 55001 audits, making them far less daunting and much more efficient. Take Oxand Simeo™ for example – it simplifies the entire process by automating documentation, consolidating asset data, and producing audit-ready reports that auditors can verify in minutes instead of days. Asset managers gain immediate access to complete audit trails, removing the need for tedious data collection. Plus, they receive ISO 55001-aligned investment plans and real-time compliance dashboards, all powered by a single, accurate data source.

The results are hard to ignore: organizations using Oxand Simeo™ report up to a 70% reduction in audit preparation time and a 12–18% cut in operating expenses [1][3]. Its predictive models, based on 10,000 proprietary aging laws, offer clear, evidence-backed justifications for maintenance and investment decisions [3]. Meanwhile, real-time dashboards ensure continuous compliance tracking, and automated change logs document every asset update with timestamps and user accountability [1]. This not only streamlines audits but also strengthens asset governance over the long term, turning ISO 55001 compliance into an ongoing capability that reduces risks and boosts stakeholder confidence [8][9].

Switching from manual processes to digital solutions delivers more than just time savings – it fundamentally changes how organizations demonstrate reliability and build trust. With transparent workflows and instant compliance insights, asset managers can shift their focus from administrative tasks to strategic planning. By automating key processes and centralizing data, Oxand Simeo™ transforms ISO 55001 audits into a seamless, predictive process that reduces stress, enhances audit outcomes, and supports sustained operational excellence and regulatory compliance.

FAQs

How does Oxand Simeo™ help cut ISO 55001 audit prep time by up to 70%?

Oxand Simeo™ takes the hassle out of ISO 55001 audit preparation by automating essential tasks and centralizing asset data. With real-time data integration, all critical information stays current and easy to access. This eliminates the need for tedious manual data collection and reduces the risk of errors.

The platform also streamlines documentation by generating detailed, audit-ready reports with just a few clicks. This not only saves time but also helps identify and address compliance gaps well before the audit date. By simplifying workflows and enhancing visibility, Oxand Simeo™ makes audit preparation faster, easier, and far less stressful.

How do AI-driven tools simplify ISO 55001 audits?

AI-powered tools are transforming ISO 55001 audits by enhancing precision, efficiëntieen predictive capabilities. These tools can handle tasks like automating data analysis, spotting risks early, and ensuring compliance with far greater ease compared to manual processes. When integrated into asset management systems, AI enables organizations to gather and analyze real-time data, keeping audit trails updated and reducing the likelihood of human errors.

On top of that, AI aids in making proactive decisions by predicting asset failures and improving lifecycle management – key aspects of ISO 55001’s emphasis on performance and risk management. This doesn’t just simplify the audit process; it also highlights ongoing improvements and strengthens operational reliability. By automating repetitive tasks, delivering actionable insights, and keeping organizations consistently prepared for audits, AI tools significantly ease the burden of compliance.

How does real-time data integration help with compliance and managing risks?

Real-time data integration provides asset managers with accurate, up-to-the-minute information about asset performance and conditions. This constant flow of data makes it easier to spot and address deviations from safety or operational standards, reducing the likelihood of failures or incidents.

By automating data collection from sensors and systems, this approach eliminates the need for manual reporting. That means fewer errors, fewer delays, and a smoother process overall. Plus, with quicker access to reliable data, decision-making becomes faster and more proactive, helping organizations stay aligned with regulatory requirements while improving operational transparency.